Snowshape Maker

24 Jan 2018

Franco Creates Custom Snowboards

Winter 2017/2018

Written By: Kristen Pope | Images: David Bowers

When Mikey Franco traveled to Japan in 2010, he had hoped to spend his days snowboarding through Niseko’s legendary powder. But a back injury sidelined him and he could barely walk when he arrived. Snowboarding powder was unthinkable.

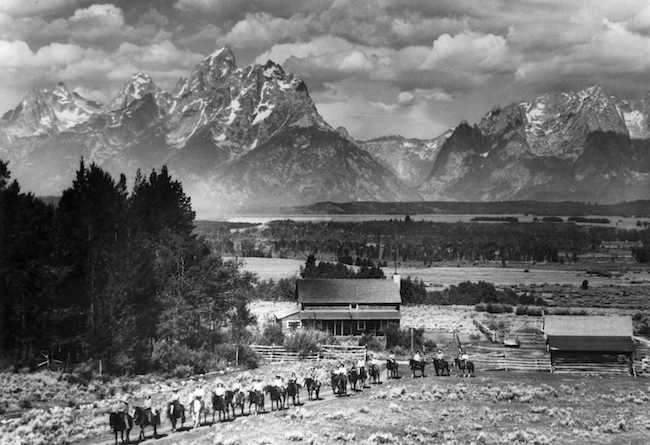

He was traveling for snowboard company Burton, and his colleagues decided to take him to a Japanese snowboard maker instead of the slopes. Franco was in awe of the artistry and precision he saw in each board. “They were so beautiful—nothing like I’ve seen in America,” he says. After he returned to the U.S., Franco was facing surgery and a long recovery period, so he decided to spend his winter making a board. He knew just how he wanted it to look: like classic Japanese perfection. Under the tutelage of his mentors at Igneous Skis, he learned all about snowboard making and decided that would be his next chapter. He had worked as a snowboarding instructor, backcountry guide, and snowboard examiner for 34 years, traveling the world for his sport, but he knew he needed to find another way to make a living. “Snowboarding seven days a week, every day, all day, from open to close was no longer appealing to me,” he says. “And it was my livelihood. When I was a guide, if I got hurt, I didn’t make any money. This was a new way to engage myself with snowboarding that was way more hyper-focused, and it was different and exciting.” His company, Franco Snowshapes, crafted 15 boards during its first full year in 2013, but this year, with three part-time employees, he’s expecting to turn out 120 or so. His handmade custom boards have amassed a lengthy waiting list. Some of the boards also have a unique local connection: They are made from Jackson Hole Mountain Resort trees. When installing and maintaining lifts, the resort often has to clear trees and Franco was able to collect a seven-foot section of a couple trees near Casper Lift. He recorded the GPS location and had the wood milled into 0.6-millimeter snowboard veneers. When people order a board made with that veneer option, they can have the exact GPS coordinates where that specific tree grew stamped onto their board. Some people have even come to the resort to find the spot in person. “It is a cool story and it falls in line with the whole farm-to-table organic food and craft brewery movement to basically know where your stuff comes from,” he says.

One of Franco Snowshapes’ newest lines, the RPK collection, also has a local touch—its name comes from the resort’s afternoon RPK forecast that predicts how good the next day’s skiing will be. The three sets of 15 boards will be handcrafted at Sego Skis in Victor, Idaho.

The allure of powder still calls Franco to the mountains, and he gets out whenever he can. He also finds time to work as a part-time backcountry guide and snowboard instructor.

“I have to be involved in snowboarding seven days a week,” he says. “I can’t rest yet to get to where I want to be.”

“It is a cool story and it falls in line with the whole farm-to-table organic food and craft brewery movement to basically know where your stuff comes from,” he says.

One of Franco Snowshapes’ newest lines, the RPK collection, also has a local touch—its name comes from the resort’s afternoon RPK forecast that predicts how good the next day’s skiing will be. The three sets of 15 boards will be handcrafted at Sego Skis in Victor, Idaho.

The allure of powder still calls Franco to the mountains, and he gets out whenever he can. He also finds time to work as a part-time backcountry guide and snowboard instructor.

“I have to be involved in snowboarding seven days a week,” he says. “I can’t rest yet to get to where I want to be.”